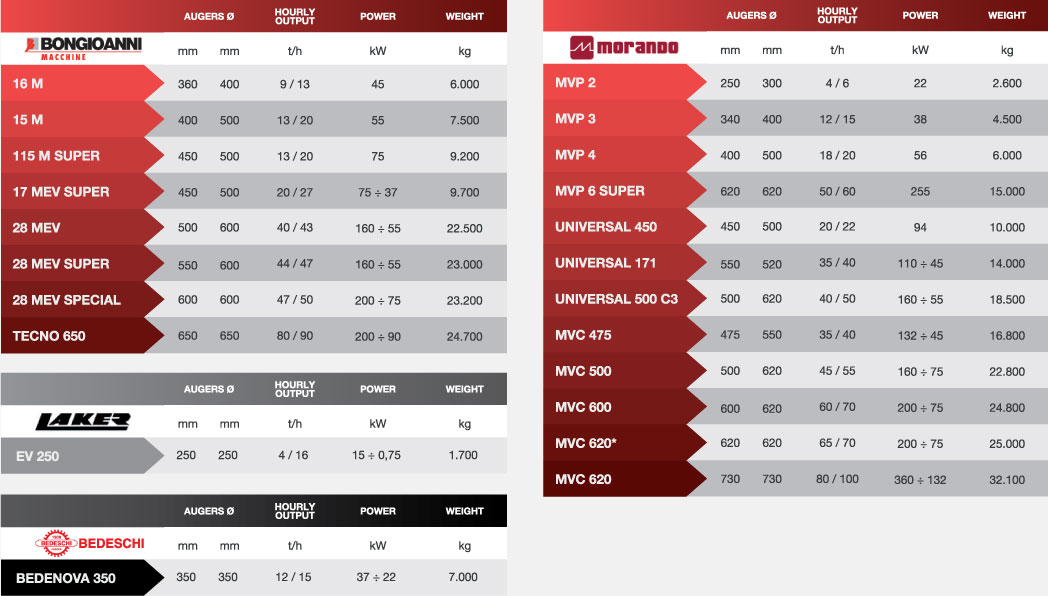

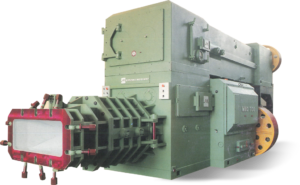

A full range of de-airing extruders are available with auger-set diameters from 300 to 700 mm and can be used together with multiple-exit shaping of different types of bricks, such as hollow bricks, facing bricks, ceiling blocks and roof tiles. Output production of our extruders ranges from 5-100 tons per hour. The technology and materials utilized guarantee high reliability, tolerance to vibrations, and resistance to abrasion with anti-wear coatings and chrome plating. They offer simple, quick maintenance together with optimal energy consumption.

Features of Extruder

- Interchangeable and split cylindrical rings with anti-wear coatings and chrome plating on request.

- Easily accessed interchangeable steel augers with anti-wear coating in tungsten carbide and chrome plating.

- Gear box including helical gears, steel shafts, and thermally treated steel pinions.

- Supporting bearings with double row rollers and self-aligning thrust blocks (SKF e FAG).

- Forced oil lubrication by means of mechanical or electric pump.

- Pneumatic clutch, assembled on the drive pulley.

- Steam unit available upon request.

Features of Feeding Mixer

- Double frontally supported steel shafts with openable grids with anti-wear coatings upon request.

- Clutch transmission with oversized-toothed gears.

- Supporting bearings with double row rollers and self-aligning thrust blocks (SKF e FAG).

- Interchangeable chrome-coated basin lining.

- Mixing blades and augers of C40 welded steel with tungsten carbide anti-wear treatment.

- Forced oil lubrication by means of mechanical or electric pump.

- Pneumatic clutch, assembled on the drive pulley.

- Oil heating unit for gears available upon request.

- Durometer or analog plastometer.