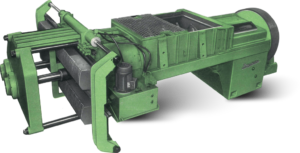

These machines are a multifunctional system for mixing, moistening, steam-heating, kneading, homogenizing, shredding and stone elimination. In addition to carrying out the usual tasks of Double-shaft mixers, these machines also filter the raw material, separating rocks, roots, and extraneous matter of any kind. Screen mixers employ two shafts with blades, equipped with a series of helices at the end. The shafts rotate in a large basin, wetting and mixing the raw material, and eventually push the mixture through a grid that prevents foreign bodies from passing through. The mixing blades can be supplied with a wear-resistant, tungsten carbide reinforcement on the external surface, together with a thick chromium plating. Double-shaft screen mixers are available with mixing basins of 2000 mm to 3000 mm and with blades and propeller diameters from 300 to 850 mm, and productivity from 15 m3/h up to 130 m3/h.

Features

- Supporting structure in welded steel.

- Interchangeable basin coatings supplied upon request, such as chrome plating.

- Front support shafts equipped with spherical roll bearings.

- Mixing blades in steel with chromium plating and wear resistant reinforcement in tungsten carbide upon request.

- Protection Grid in mixing zone.

- Front Grill in steel with chromium plating and wear-resistant reinforcement and with hydraulic control for rapid replacement during operations.

- Gearbox with double reduction containing dismountable steel support shafts and helical gears.

- Forced lubrication by motorized pump.

- Driving pulley with pneumatic clutch.